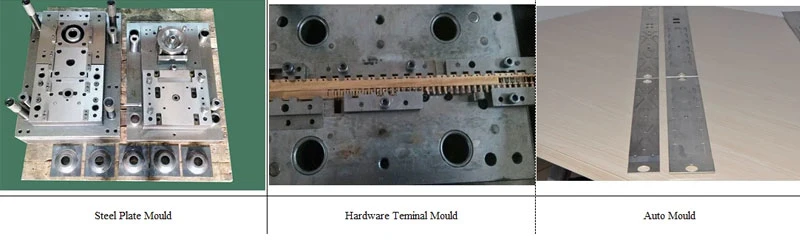

Progressive Stamping Punch Metal Stamping Mold Including Stainless Steel Die Metal Stamping Press

Overview Package Size 300.00cm * 70.00cm * 120.00cm Package Gross Weight 120.000kg Stamping Mold Product Description but

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | YT-M |

| Processing Method | Punching and Shearing Mould |

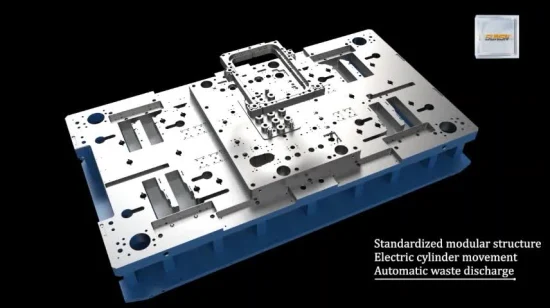

| Technics | Progressive Die |

| Process Combination | Composite Mould |

| Manufacturing Technology | Computer Technology |

| Driving Motor Type | Permanent Magnet |

| Mold Cavity Technology | CNC Milling |

| Milling Speed | High Speed |

| Parts Detection Method | Geometric Detection |

| After-sales Service | Outside Engineer Service |

| Accessory | Go with High Speed Punch Press |

| MOQ | 1000PCS |

| Shaping Mode | Punching Mold |

| Transport Package | Wooden Package |

| Specification | YT |

| Trademark | YITUO |

| Origin | China |

Packaging & Delivery

Package Size 300.00cm * 70.00cm * 120.00cm Package Gross Weight 120.000kgProduct Description

Stamping MoldProduct Description

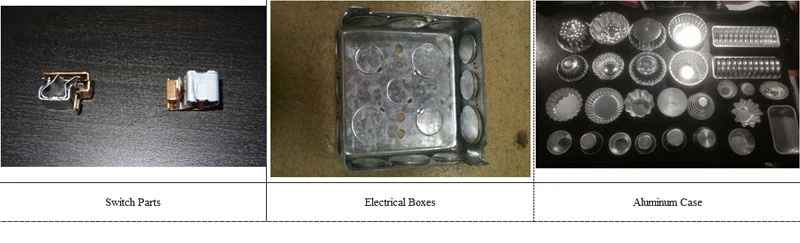

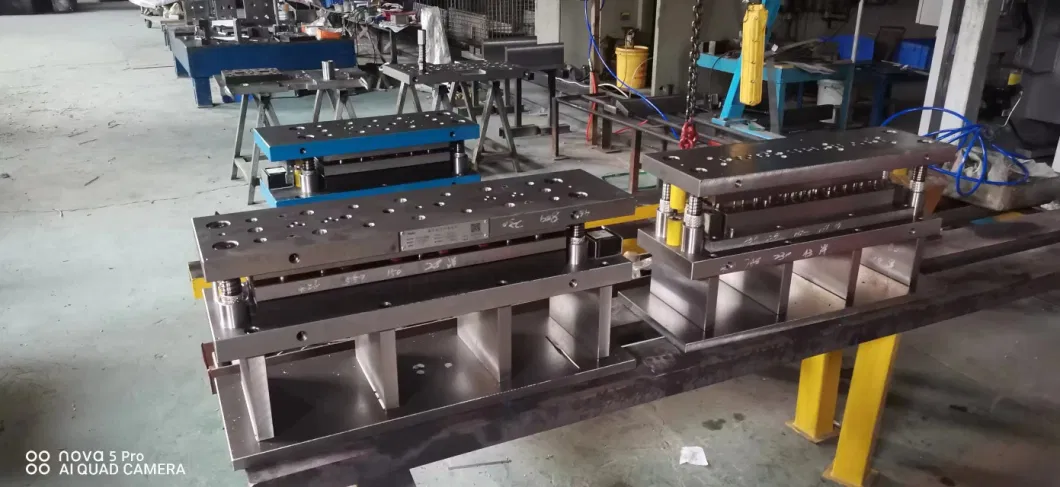

button, stators, terminals progressive molds

1. use for process procedure more than 1 various products punching, various products widely used in mobile, tooling, commodity, etc. industry production.

2. work with a high-speed press machine, punching SPM of more than 200, with production times of 10 per day. As a result, avoid the shape deviation when multiple dies and presses work at the same time by using general dies and presses to produce big quantity products, better guarantee the product quality. Reduce facility requirements, as a result, reduce factory space requirements.

3. save material by more than 10%.

4. use coil material and automatic feeder for production, greatly reduce labor intensity, and save labor costs.

5. different models can be designed according to clients' products' different shapes, sizes, patterns, etc. requirements.

Product Parameters| Product Name | stamping die/mold/mold/tool | Drawing Format | igs,stp,prt,asm,pdf,dwg,dxf |

| Material | SKD11,DC53,Cr12MOV,CR12,SKD61 etc. | First Tria | 15- 25 days after the mold drawing confirmed |

| Design Software | AutoCAD, PRO/E, UG, Catia, Dynaform, Solidworks, etc. | Die Life | 1,000,000~ 3,000,000 shots |

| Die Type | stamping die, compound die, progressive die, punched hole, cutting die, deep drawn die, or according to your parts | Note | The products are here to show the scope of our manufacturing capabilities and it not for sale |

Application

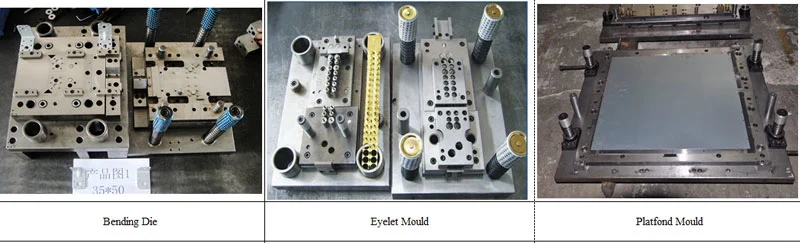

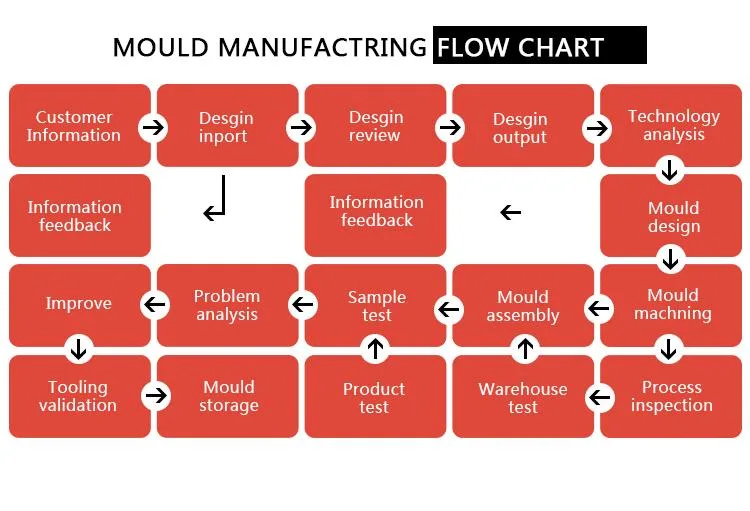

In making any sheet-metal components, we are using a power press on which we mount the die of the required component. The tool / dies on either of these presses are of the following type:

-Simple Blanking dies

-Progressive or Muti Cavity dies

-Compound plus Progressive dies

-Compound dies