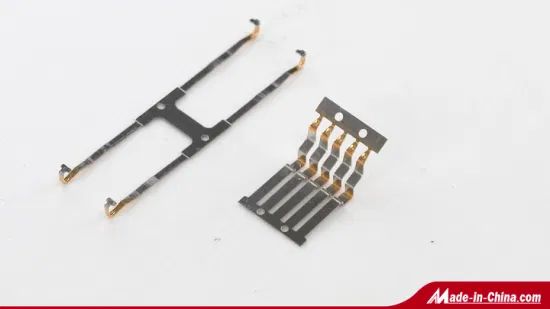

Precision Metal Stamping Parts Bending Forming Metal Sheet Brackets

Precision metal stamping parts bending forming metal sheet brackets Product Description Similar product Company Profile

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | EL0253-00 |

| Fine Blanking | Double Acting |

| Process | Forming Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.03-0.05mm |

| Customized | Customized |

| Function | Paper Cutter |

| Transport Package | Tray/Carton |

| Trademark | ELMAX |

| Origin | China |

| Production Capacity | 20000pieces/Day |

Product Description

Precision metal stamping parts bending forming metal sheet brackets| STAMPING EQUIPMENT | ||

| ITEM NAME | SPECIFICATION | QUANTITY(SET) |

| Taiwan Mingxu Precision high-speed punching machine | 25T | 1 |

| Taiwan Mingxu Precision high-speed punching machine | 45T | 2 |

| Taiwan SEYI Precision punching machine | 60T | 3 |

| Taiwan SEYI Precision punching machine | 80T | 1 |

| Taiwan CHINFONG Precision punching machine | 110T | 1 |

| Wangpan precision grinding machine | 2 | |

| Wangpan precision milling machine | 2 | |

| Marriott Precision 2.5 Dimensions | 2 | |

| Marriott Precision Projector | 2 | |

| TOTAL | 8 | |

Product Description

| Product Type | metal stamping, Multistep/single Progressive Dies |

| material | SUS420, Phosphor bronze,copper, thickness: 0.2mm-0.4mm |

| Process Methods | Punching/Stamping/Bending stamping |

| Tolerance | In general:+/-0.05 mm, can be more precision,according to your requirement. |

| surface treatment | copper plating+nickel plating |

| Applications | Mainly used in cell phone component,headset |

| Delivery time | For stamping ,20-25 working days(including surface finishment) ,Mass production: 2-3 weeks |

| Advantages | Good Quality with strict inspection process/Competitive Price and prompt delivery time |

Similar product

Company Profile

As a one-stop OEM/ODM service provider, ELMAX has always been committing to the technology of stamping and plastic injection molding ; Focusing on tooling and mass production of Stamping parts, Injection-molded plastic parts and Insert-molding components. The products range is inclusive of hardware stamping parts, metal stamping, sheet stamping,plastic injection parts used for security camera/ CCTV camera, optical transceiver and varies of relays. The main customers of ELMAX are domestic well-known companies and partners comes from all of the world especially from Europe/America, such as FINISA, PVS, Amphenol,TTI and so on.

Metal stamping workshop

Quality guiding principle

Quality is the lifeblood of an enterprise, and customers are forever mentors.

Management Philosophy

Related Products

-

![Stamping Die/Press Die/Punch Die/Hardware Die for Microwave Oven Sheet Metal Parts /Component/Product]()

Stamping Die/Press Die/Punch Die/Hardware Die for Microwave Oven Sheet Metal Parts /Component/Product

-

![Transfer Fingers Nut Forming Tooling and Dies]()

Transfer Fingers Nut Forming Tooling and Dies

-

![China Custom Rotator Stator Automotive Hardware Terminal Connector Electronic Part Combination Compound Transfer Progressive Sheet Metal Stamping Die]()

China Custom Rotator Stator Automotive Hardware Terminal Connector Electronic Part Combination Compound Transfer Progressive Sheet Metal Stamping Die

-

![Metal Hardware Copper Stamping Parts Small Battery Spring Electrical Contacts]()

Metal Hardware Copper Stamping Parts Small Battery Spring Electrical Contacts