Customized High Precision Sheet Metal Stamping Parts Spring Stainless Steel/Brass/Copper Clips Contact

Customized High Precision Sheet Metal Stamping Parts Spring Stainless Steel/Brass/Copper Clips Contact Our manufacturing

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | WF-SA |

| Surface Processing | Electroplating |

| Fine Blanking | Open |

| Process | Forming Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.2mm |

| Customized | Customized |

| OEM and ODM | 100% with Drawings and Samples |

| Delivery Time | 30 Days After Payment |

| Technology | Casting + Machining |

| Unique | 15 Years of Manufacturing |

| OEM Package | Anti-Rust Package System |

| Inner Package | Carton Box/Plastic Bag |

| MOQ | 2000 Pieces for Trial Order |

| OEM Sample | About 10 Days |

| Quality Stardard | DIN/JIS/BS/ASTM/CE |

| Technics | Stamping, Punching, Grinding |

| Name | Sheet Metal Stamping Parts for Machine Housing |

| Material Type | Aluminum/Brass/Stainless Steel/Cooper Sheet |

| Transport Package | Plywood Box |

| Specification | CE, SGS |

| Trademark | ShengAo |

| Origin | Weifang, Shangdong, China |

| HS Code | 8483500000 |

| Production Capacity | 50000PCS/Month |

Product Description

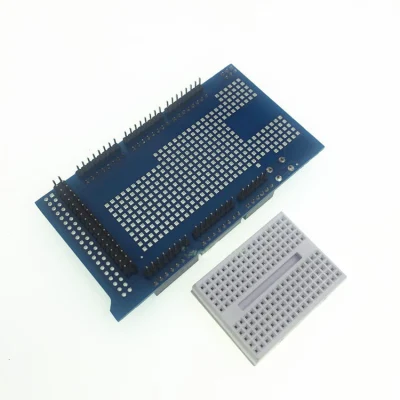

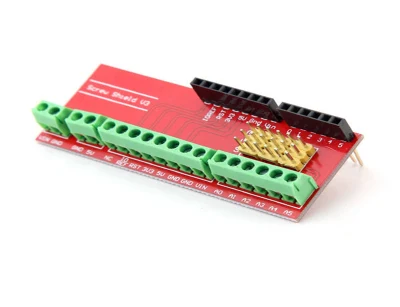

Customized High Precision Sheet Metal Stamping Parts Spring Stainless Steel/Brass/Copper Clips Contact Our manufacturing capability: ·Punch range from 16T to 500T ·Hydraulic plate shears ·Bending machine ·Hydraulic draw-bench ·Blanking, piercing, bending, forming, and deep drawn

1. ISO9001-2008.

2. Has advanced euipment and over 15 years experience.

3. Price: Competetive price, Precision made. Experience & Reasonable QC that you can reply on.

4. Process: Precision made. Experience & Reasonable QC that you can reply on Each part would be given 100% test and tryout before shipment.

5. Adequate supply capacity. Punctual delivery time.

| Material | Carbon steel, stainless steel, brass, zinc/aluminum alloy etc |

| Surface treatment | Galvanized, zinc plating, powder coating, electroplate. |

| Application | Construction parts, furniture hardware, electronic hardware, machinery parts, art-ware |

| Tooling room | Yes, mold was made by ourselves. |

| Machinery capability | Hydraulic press machine, cold chamber machine, machining center, the machines for bending, grinding, milling, drilling, welding, polishing, shot blasting machine. |

| Packing | Film/Carton/Plywood box, or according to customer's requirement. |

| OEM/ODM | Acceptable |

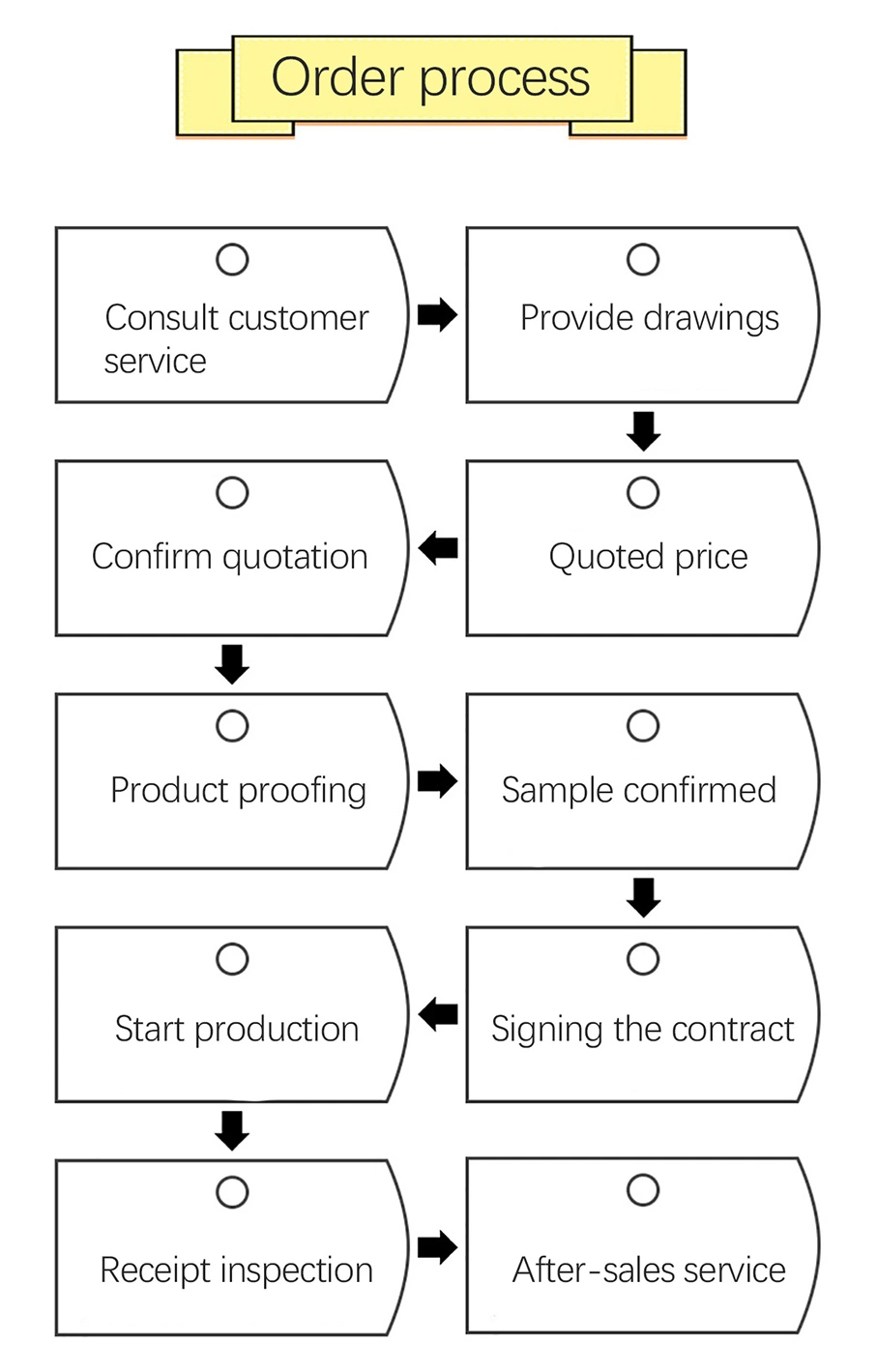

Our promise:1.Offering design and improvement scheme freely.2.Offering video and photos with details freely during production.3.Helping customers to do factory inspection freely for his other Chinese suppliers.4.We have our own factory, and 80% of our employees have been working for more than 10 years. 5.Producing completely according to the accuracy of drawings,assembly measurement to detect function and strict quality control to ensure 0 return rate.6.99% orders can be ensured delivery time.7.Quote can be offered within 24 hours fastest.8.Delivery time is only 7 days fastest.9.Responding to the enquiry within 2 hours.10.The materials we use are optimal.11.24 hours online service.12.The lowest price with the same quality and service.13.Logistics arrangement with high performance to price ratio.14.The most suitable packing method to different products.

Q: Why choose Shengao product? A: We shengao have our own plant Weifang Shengao machinery Co., Ltd, therefore, we can surely promise the quality of every product and provide you comparable price. Q: Do you provide OEM Service? A: Yes, we provide OEM Service. Q: Do you provide customized Sheet Metal Stamping/Stamped Parts/Punching Parts? A: Yes. Customers give us drawings and specifications, and we will manufact accordingly. Q: What is your payment term? A: We provide kinds of payment terms such as L/C, T/T, Paypal, Escrow, etc.

If there is anything we can help you, welcome to contact us anytime!