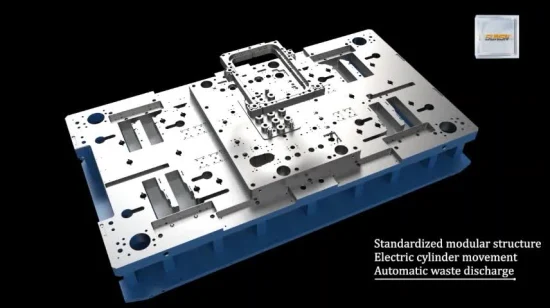

Metal Parts Base Plate Hot Stamping Parts Mount Bracket Progressive Die

Mounting plate bracket We use different type of stamping machine (cover from hand to precision punch)to produce metal st

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | JH-Y022 |

| Process | Forming Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.1mm |

| Customized | Customized |

| Transport Package | Boxes, Carton, Pallet or as Per Customer′s Require |

| Specification | Thickness: 0.1mm-12mm |

| Trademark | OEM |

| Origin | Ningbo, China |

| Production Capacity | 100000PCS/Month |

Product Description

Mounting plate bracketWe use different type of stamping machine (cover from hand to precision punch)to produce metal stamping and pressing. According to customer's order quantity,we offer the most cost-effective way to your project, we can use laser cutting,Single-shot or continuous progressive die automated production.

Processing range: blanking, cutting, forming, rolling, drawing, bending, flaring, shrink tube, drilling, tapping, spot welding nuts or screws.

Thickness:0.1mm-12mm

Surface treatment: Plating, Galvanization, Anodized and Powder coating

* Plating: Zinc, nickel, chromium, silver, etc.

* Anodized and Electrophoresis

* Paint and Powder

* Vibration deburring, polishing and chemical treatment

* Screen printing, color printing and laser engraving.

| 1.Name | Mounting plate bracket |

| 2.Material | Carbon steel; Stainless steel, aluminum alloy; Brass alloy; |

| 3.Machining processes | Metal fabrication, machining, welding, forming, shaping, punching, etc. |

| 4.Surface treatment: | Antiqued Rustic Bronze, Imitation Bronze, Polished Brass Lacquered, Polished Chrome Plate, Satin Chrome Plate, Satin Nickel Plate,etc. |

| 5.Machinery and equipments | CNC machining center; General planning and grinding machine;General punching machine, CNC turning center; Wire EDM, 4 or 5 axis-CNC center processes. |

| 6.QC | 1) Technicians self-check in production 2) Engineer spot check in production 3) QC inspects after mass production finished 4) International sales who were trained the technical know-how spot check before shipping |

| 7.Packing | Boxes, Carton, Pallet or as per customer's requirement |

Advantage:

1 | More than 10 years experience for serving satisfied customers |

2 | OEM service and Design service are available |

3 | Reply to your inquiries in 24 hours. |

4 | Quality control with professional experienced QC team |

5 | Delivery the high quality goods on time. |