Make Progressive Hardware Tooling Molding Stamping Die

Package Size 400.00cm * 400.00cm * 400.00cm Package Gross Weight 40.000kg PRODUCT DESCRIPTION: We provide high quality s

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | hs-1099 |

| Processing Type | Metal Spinning |

| Material | Alloy Steel |

| Mould | Multistep Progressive Dies |

| Surface Processing | Spraying |

| Fine Blanking | Double Acting |

| Process | Forming Process |

| Industry | General Stamping |

| Tolerances | 0.01mm |

| Customized | Customized |

| Hardness | as The Request HRC, Hb, Bhn... |

| Field | Aerospace Part, Marine Parts, Mining Parts |

| Standards | DIN, ASTM, GB, JIS, ANSI, BS |

| Finishing | Anodized, Chrome Plating, Powder Coat |

| Quality Guarantee | 1 Year |

| Transport Package | Wooden Box or Carton |

| Specification | According to the drawing |

| Trademark | HISEA OR OEM |

| Origin | China |

| Production Capacity | 20000 Piece/Pieces Per Month |

Packaging & Delivery

Package Size 400.00cm * 400.00cm * 400.00cm Package Gross Weight 40.000kgProduct Description

PRODUCT DESCRIPTION:We provide high quality standard manufacturing service for CNC machining/ forging / casting / stamping...

Pls sending us All components' drawings and designs.we can quote and make it accordingly.

Material

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS316L,SS416 ,AISI 440C,17-4PH etc. |

| Steel | mild steel, Carbon steel, 4140, 4340,65Mn,60Si2Mn, Q235, Q345B, 1020steel, 1045steel,A106,A105, A570-50,CR-MO4130,Astm A487 grade 9A, 52100 Bearing steel ,S45c, Sm490A, AVP/S235JRG2,DD14, 1.0037 ,etc, ASTM 1197-47, 25CRMO4V,SCM435, 11SMNPB30,1.0718,.A36 |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H62, H68, H80 ,Bronze 660, C93200,Bronze CDA873 or 956,CDA873,C95600,MAILEABLE IRON ASTM A47-77, etc. |

| Copper | C11000,C12000,C12000 C36000,C100 etc. |

| Aluminum | AL1100,AL6061, Al6063-T6, AL6082, AL7075, AL5052, A380 etc. |

| Iron | 1213, 12L14, 1215,ductile iron astm a536, 60-40-18, 60-45-12, FE E420,etc |

| Plastic | ABS, PC, PE, POM, Delrin 2700 NC010, Nylon, PP,PEI, Peek etc. |

Finishing:

| Zinc plating, Chrome plating, Nickel plating, Tin plating, Polishing, Anodizing, Power-coating, Dacromet, Oxide black, Sandblast Anodizing, Electroless nickel, Fe/Zn8/C PER ISO 2081, etc. |

| Specifications: | |

| Design: | We use the most advanced mould design software Auto CAD, Pro/E, Solidworks, UG (dwg, dxf, IGS, STP, X-T) |

| Manufacture: | We use advanced technology, unmatched skill, professional and advanced equipment size range from 15T-10000T, and experienced technicians to fit our customers requirements, like tooling manufacturing,robot welding,forging, steel casting, stamping and surface treatment service |

| Process and Capability: | Cnc machining, Casting,Forging,Progression die, Stamping, deep drawing, Bending, Punching, Threading, Welding, Tapping, Riveting, Grinding, Laser cutting,Metal Fabrication,forming,spinning, CNC Punching, Plasma cutting, Goffered, Stretch forming ,Tig/Mig Welding,Assembling, Shearing, Blanking, CNC Bending............, |

| Price Terms: | Fob Ningbo or Shanghai or any other port in CHINA |

| Lead time: | 20-50days based on the different products |

| Packaging: | Wooden package and canton case or as per customers' requirement |

| Certification: | ISO9001:2018 , SGS , TS16949,API 8C |

| Industry: | these parts are used in hydraulic presses, press line automation and die handling equipment,Automotive, Electrical, Building, Furniture, Machine assembly, Computer, Air industry , Oil field Equipments, Marine equipments, Mine equipment,Agricultural Machines,Transportation Equipments, OEM/ODM Electronics...... |

DETAILED PHOTOS:

OUR ADVANTAGES:

1.Good Quality with strict inspection process. control the tolerance up to +,-0.002MM.2.Competitive Price and prompt delivery time.3. International Quality Certified4.Skilled workers5.Warranty After-sales-service

FAQ:

Q1: How can I get quote ?A1: pls send us PDF,JPG,or other 2D files and 3D drawings. if you don;t have drawings. pls send me samples.Q2: How you guarantee the quality?A2: Our production will be strictly comply with the drawing requirements.we offer details photos and inspected reports to let you confirm before shipment.we will take the responsibilty for any quality issue.Q3: What is payment term?A3: 30% depoist in advance and the balance to be paid against the copy of BL.or LC at sight.Q4: How about the shipment and package?A4: If you have nominated forwarding company, we can contact him, if you don't have .my company will organise the best-service forwarding company with the lowest shipping cost.Q5: How to pack the cargos?A5: If you have special packing request, pls send us design, my company will make the package exactly according to your designs.or my company use our own good and standard package (carton or wooden box, or pallet or others according to different products )

Related Products

-

![China Custom Rotator Stator Automotive Hardware Terminal Connector Electronic Part Combination Compound Transfer Progressive Sheet Metal Stamping Die]()

China Custom Rotator Stator Automotive Hardware Terminal Connector Electronic Part Combination Compound Transfer Progressive Sheet Metal Stamping Die

-

![Metal Stamping Mold Hardware Deep Drawing Progressive Sheet Die Manufacturer]()

Metal Stamping Mold Hardware Deep Drawing Progressive Sheet Die Manufacturer

-

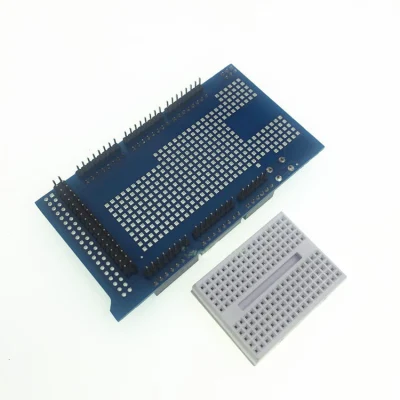

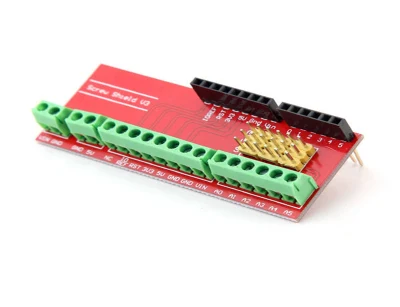

![R3 Prototype Development Board Proto Screw Shield V2]()

R3 Prototype Development Board Proto Screw Shield V2

-

![L298p Motor Driver Module H]()

L298p Motor Driver Module H